We have a strong R&D and design team, especially in the field of instantaneous electric water heaters with unparalleled advantages and experience

Foshan Shunde Choig Electronic Technology Co., Ltd. loated in CIMC Smart Valley Technology Park. We are a technology-based company that integrates research and development, design and manufacture of water heating, electric heating, low temperature and constant temperature control and other household and commercial electrical controllers.

We have a strong R&D and design team, especially in the field of instantaneous electric water heaters with unparalleled advantages and experience.

Our Advantage

Our company have rich experiences in water heating field, electric heating field and heat pump field. We have software engineer,hardware engineer, testing engineer and management engineer, which make our development project can be Creativity and stability.

we will evalute from our clients about the project on technical feasibility and cost feasibility. After confirmation from our clients we will start the development and we will make the samples testing in our side before delivery them to our clients. When our clients testing in there products with our control baords we will get the feedback and adjust according to the feedback and requirement till it is ok. till the whole project match your requirement. then the development will finished. Even if the customer has any adjustments or new requirements during use, we will continue to adjust the electronic control solution according to the customer's requirements until the project is terminated.

For the quality control on development, we have Rigorous development process, covering from design schematic review to component selection to final functional test and performance test. We have standard design specifications to ensure that every detail and requirement of our design is free of loopholes and flaws. We have The risk assessment table simplified from DEFEAM ensures that our solutions have sufficient awareness and prevention of various design and application risks in the application field

We have made many outstanding achievements in the fields we are good at, such as precise constant temperature technology in the field of instant water heater control, heating + shower + built-in water tank multifunctional control technology in the field of electric wall-mounted boiler control, and trigeneration control system in the field of heat pump We will make more technological breakthroughs in these and other areas to bring more and better experience and convenience to our customers.

Experienced Team

01

We have software engineers, hardware engineers, assistant engineers and project engineers, all of whom are elites in various professional fields for more than ten years. Can quickly understand and realize customer intentions and provide rigorous and practical electronic control solutions.

Perfect Testing Equipment

02

Testing is the necessary for development because we must confirm the control board is match the requirement of our clients and in the same time we must make sure our control solution Comply with industry standards. So the testing equipment can test our control boards functions and performance, for example Lightning surge test, high temperature and humidity test, anti-interference test, etc.We have We have a complete laboratory that can conduct multi-project tests and match the testing and verification under similar internationally accepted safety regulations and energy efficiency standards.

Rigorous and Complete service Awareness

03

Our technical service includes three stages. The first stage is the stage of communicating with customers about project development requirements. We will fully listen to customers' requirements, try to digest the technical difficulties and characteristics involved in the other party's requirements, and put forward reasonable suggestions based on our experience in order to achieve the best solution; the second stage is the project establishment and development stage. At this stage, we must not only strictly follow the development process and highly standardize the development standards, but also remember to fully absorb customers' opinions and improve the solutions during the testing process of both parties; the third stage is the after-sales service and project upgrade service stage. We humbly accept the feedback from consumers and the market collected by customers during the product sales process, further adjust and improve the solutions, make our solutions more suitable for customers and the market, and continuously investigate market needs to provide support for customers' further upgrade needs for solutions

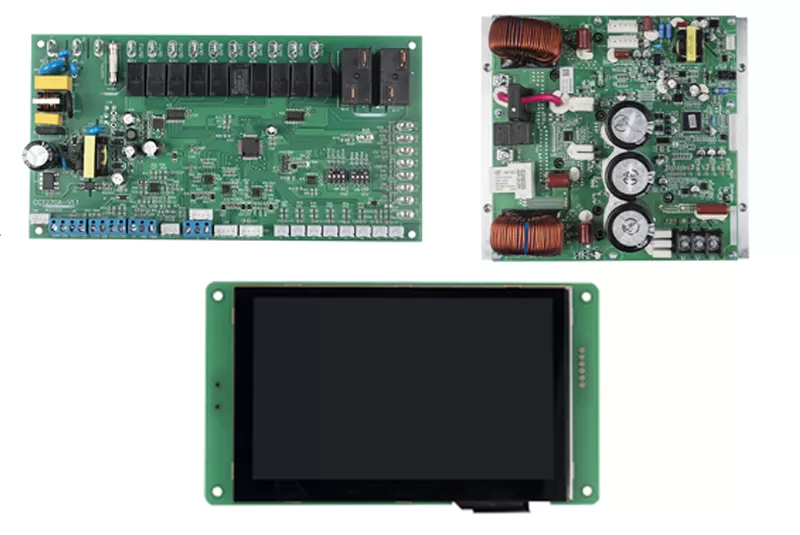

Get Started with Scheme Design + PCBA

We provide one-stop service of scheme design + PCBA, integrating design and manufacturing, which can ensure that our electronic control board perfectly carries our design scheme.

Contact UsOur Advantage

Choig Expands in the Middle East: New Branch for Energy-Efficient Electronic Control Solutions

The US-China tariff war reshapes the global manufacturing landscape, structural adjustment of electronic control demand and corporate strategic breakthrough

The European trigeneration hydraulic module project that our company is about to develop is about to be completed

Jul. 28, 2025

Choig Expands in the Middle East: New Branch for Energy-Efficient Electronic Control Solutions

Recently, our company is preparing to establish a branch in the Middle East. This major strategic move marks a key step in the company's global layout process.

Jun. 26, 2025

Since the United States upgraded its tariff policy on China in 2024, the global manufacturing supply chain has been undergoing a deep adjustment. Labor-intensive industries represented by power tools, auto parts, and consumer electronics have accelerated their migration to low-cost regions such as Southeast Asia, Mexico, and Eastern Europe. It is worth noting that the "reciprocal tariff" policy implemented by the United States in April 2025 further changed the migration logic: Southeast Asian countries such as Vietnam and Thailand face high tariffs of 46% and 36%, forcing companies to shift their production capacity to regions with lower tax rates such as Africa and Latin America.

Feb. 10, 2025

The European trigeneration hydraulic module project that our company is about to develop is about to be completed. This project is highly anticipated in the European market.