We are a technology-based company that integrates research and development, design and manufacture of water heating, electric heating, low temperature and constant temperature control and other household and commercial electrical controllers.

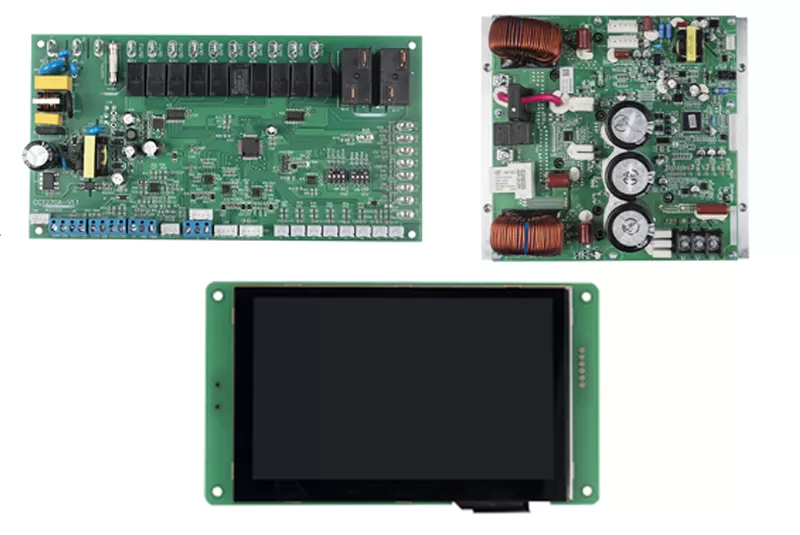

Heat Pump Control Board Design

Heat pump control board is the central electronic component that manages and coordinates all operations of a heat pump system. It serves as the "brain" of the unit, responsible for executing control algorithms, interpreting sensor inputs, regulating compressor cycles, managing defrost sequences, controlling fan speeds, and handling communication with external systems such as thermostats or building management systems.

At Choig, each heat pump control board is designed to provide precise and reliable control for both residential and commercial HVAC systems. Whether used in air-to-water heat pumps, ground source systems, or hybrid energy solutions, the control board plays a vital role in optimizing energy efficiency, ensuring safety, and enabling smart functionality.

Key Functions of a Heat Pump Control Board:

Temperature Regulation: Monitors temperature sensors and adjusts system output accordingly.

Compressor Control: Starts, stops, and modulates the compressor based on load demand.

Defrost Logic: Automatically detects frost conditions and initiates a defrost cycle.

Fan and Valve Control: Coordinates fan speed, expansion valve operation, and reversing valve switching.

Communication Protocols: Interfaces with thermostats or building management systems via RS485, Modbus, CAN, or wireless options.

Fault Detection: Continuously checks for operational errors and triggers alarms or shutdowns if needed.

Applications of Heat Pump Control Boards

| Application Scenario | Problem Solved by Heat Pump Control Board | How Choig's Control Board Solves It |

|---|

| Air Source Heat Pumps (ASHP) | Frequent frost accumulation reduces efficiency in cold climates | Integrated intelligent defrost logic with sensor-based cycle triggering ensures timely and efficient defrosting |

| Ground Source Heat Pumps (GSHP) | Poor coordination of pump and compressor leads to energy waste | Real-time temperature sensing and dynamic pump control reduce energy consumption and improve thermal balance |

| Commercial Central HVAC Systems | Complex systems with multiple compressors are hard to synchronize | Choig’s boards support multi-compressor coordination and staged startup logic, improving system stability |

| Heat Pump Water Heaters (HPWH) | Inaccurate tank temperature control results in overheating or underheating | Precision NTC temperature sensing and PID control maintain stable hot water delivery |

| Low Ambient Temperature Heat Pumps | System fails to operate below −10°C due to frost or compressor errors | Choig boards use extended temperature logic and robust start-up algorithms tested down to −25°C |

| Hybrid Heat Pump + Boiler Systems | Manual switching between energy sources causes inefficiency | Automatically prioritizes heat pump or boiler based on load demand and energy cost logic |

| OEM Custom HVAC Systems | Off-the-shelf control boards lack necessary interfaces or firmware | Choig provides custom I/O mapping, firmware development, and communication protocol support (RS485, CAN, Modbus) |

| IoT-Enabled Smart Heat Pumps | No remote diagnostics or OTA firmware updates | Choig offers optional Wi-Fi/Bluetooth modules for remote monitoring, error logging, and online firmware upgrade |

Customization Support for Heat Pump Control Board Design

Choig provides full customization services for heat pump control board design to meet the specific requirements of OEMs and system integrators. From hardware circuit layout to firmware programming and communication protocol matching, all aspects of the board can be tailored to support unique HVAC system configurations.

With over 15 years of experience in control board manufacturing, Choig’s engineering team works closely with customers to optimize performance, reliability, and cost efficiency.