Read More

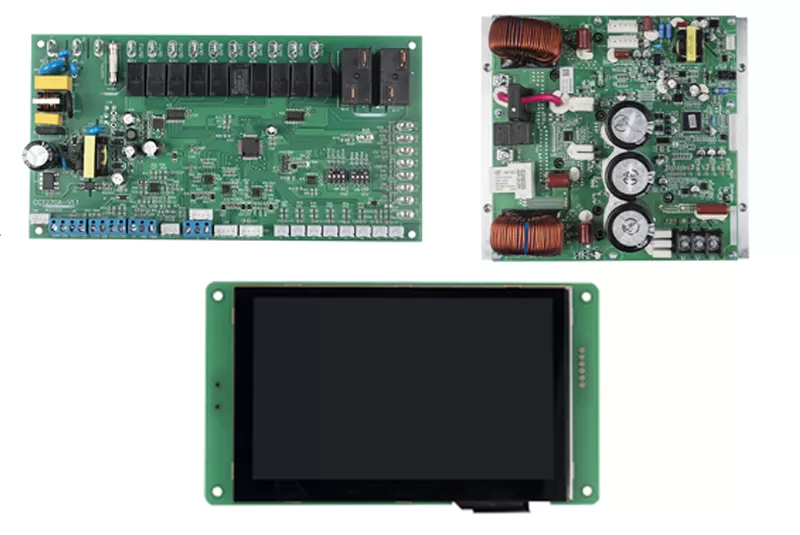

Get Started with Scheme Design + PCBA

We provide one-stop service of scheme design + PCBA, integrating design and manufacturing, which can ensure that our electronic control board perfectly carries our design scheme.

Contact UsLatest News&Blog

Our Advantage

Our company has established a branch in the Middle East to lay out a new blueprint for the electric control business

The US-China tariff war reshapes the global manufacturing landscape, structural adjustment of electronic control demand and corporate strategic breakthrough

The European trigeneration hydraulic module project that our company is about to develop is about to be completed

Jul. 28, 2025

Recently, our company is preparing to establish a branch in the Middle East. This major strategic move marks a key step in the company's global layout process.

Jun. 26, 2025

Since the United States upgraded its tariff policy on China in 2024, the global manufacturing supply chain has been undergoing a deep adjustment. Labor-intensive industries represented by power tools, auto parts, and consumer electronics have accelerated their migration to low-cost regions such as Southeast Asia, Mexico, and Eastern Europe. It is worth noting that the "reciprocal tariff" policy implemented by the United States in April 2025 further changed the migration logic: Southeast Asian countries such as Vietnam and Thailand face high tariffs of 46% and 36%, forcing companies to shift their production capacity to regions with lower tax rates such as Africa and Latin America.

Feb. 10, 2025

The European trigeneration hydraulic module project that our company is about to develop is about to be completed. This project is highly anticipated in the European market.